Baffles are necessary to create enough turbulence for mixing and guiding the liquid flow in the tank. Without baffles, liquid mass will swirl around forming vortex with little or no mixing.

Impeller power consumption is depending on baffles. Minimum three numbers of baffles are recommended. Off center or angular mounting of agitator can minimize vortexing and create semi baffled condition.

Knowledge Base

What is the role of baffles?

What is the role of Stabiliser?

When can we use "Static Mixer"?

Can we change the direction of rotation of agitator?

Can we use same agitator for different application?

When can we use Variable speed drive for Agitators?

What is the preferred tank geometry for mixing vessel?

Can Ceecons India help in basic engineering of mixing process and vessel design?

What is the role of baffles?

What is the role of Stabiliser?

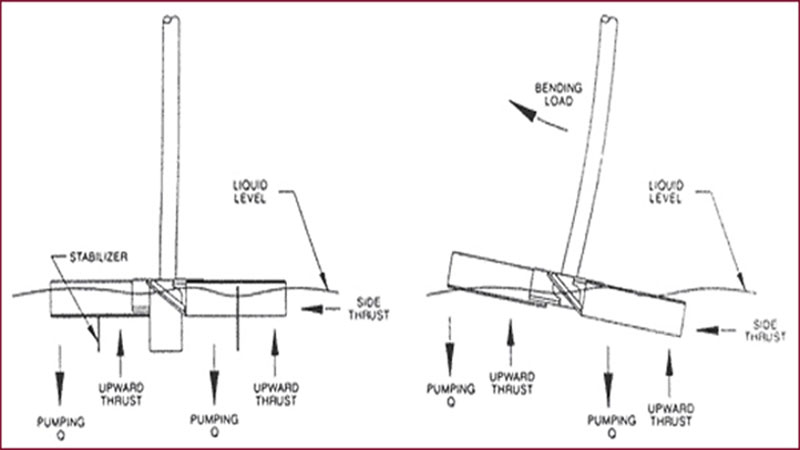

Sometime, we may need to maintain agitation while liquid level in the tank is lowered. As a general rule, operating mixers through draw-down is not desirable. A mixer which operates continually through draw-down will experience severely increased loading on the gear drive, and added stress to the mixer shaft.

improved service life, the minimum liquid coverage above the impeller is generally one (1) impeller diameter or more. Optimum process results are often obtained with coverage of two (2) or more impeller diameters.

The lower impeller of a gear-driven mixer with a shaft length longer than 1200 mm generally require downward extending stabilizers. Stabilizers come in the form of rings or fins. The object of stabilizers is to have some impeller mass extending down into the process liquid when the liquid level is even with the level of the impeller in the tank. The force of liquid against the impeller is upward and to the side. Without stabilizers, the impeller will kick out the solution and it puts severe stress on the shaft.

improved service life, the minimum liquid coverage above the impeller is generally one (1) impeller diameter or more. Optimum process results are often obtained with coverage of two (2) or more impeller diameters.

The lower impeller of a gear-driven mixer with a shaft length longer than 1200 mm generally require downward extending stabilizers. Stabilizers come in the form of rings or fins. The object of stabilizers is to have some impeller mass extending down into the process liquid when the liquid level is even with the level of the impeller in the tank. The force of liquid against the impeller is upward and to the side. Without stabilizers, the impeller will kick out the solution and it puts severe stress on the shaft.

When can we use "Static Mixer"?

Static mixer is basically in line mixer incorporated in a pipe line. There are no moving parts. Carefully designed mixing elements divide the flow, mix the constituents and reverse the flow at each element ensuring uniform mixing. Static mixers are used where one or more streams are to be mixed in a pipe.

Can we change the direction of rotation of agitator?

No; The flow pattern of some impellers changes if direction of rotation is changed. Power consumption also may vary with change in direction of rotation. Please follow the manufacturer's recommendation.

Can we use same agitator for different application?

No; Agitators are designed for specific process condition, liquid characteristics and vessel geometry .In case of change in any of the above parameters, please contact the manufacturer.

When can we use Variable speed drive for Agitators?

Variable speed is recommended

If same vessel is used for different process

In case of variation in mixing volume

If the process demands different degree of mixing during reaction

If raw materials are low viscous but viscosity changes during process ( e.g.;polymerization)

What is the preferred tank geometry for mixing vessel?

Various geometrical shapes are used for process and storage vessels. For small volume with sufficient liquid height, conical bottom is preferred. But collection of solid particles at bottom will be a problem.

Mixing also difficult with conical bottom. Flat bottom tanks are easy to fabricate and widely used in industries especially for large tanks. The tanks could be either cylindrical or square/rectangular.

Cylindrical tanks with dished end are ideal for mixing vessel. Height to diameter ratio shall be max. 1.2. Larger ratio calls for multiple impeller, longer shaft and bottom bearing. Smaller ratio will require larger impeller and larger torque.

Mixing also difficult with conical bottom. Flat bottom tanks are easy to fabricate and widely used in industries especially for large tanks. The tanks could be either cylindrical or square/rectangular.

Cylindrical tanks with dished end are ideal for mixing vessel. Height to diameter ratio shall be max. 1.2. Larger ratio calls for multiple impeller, longer shaft and bottom bearing. Smaller ratio will require larger impeller and larger torque.

Can Ceecons India help in basic engineering of mixing process and vessel design?

Certainly. Ceecons India can render basic engineering service for your mixing problems free of cost without any obligation.